SAWBLADES AND MACHINERY

Saw blades are the toothed cutting elements that are replaceable, used in a variety of hand tools, portable and stationary power tools. They are used to cut masonry, timber, metal, and other materials. Although it may appear to be a minor operational detail, blade performance has significant impacts on several key business areas. Using the incorrect blade will result in poor quality cutting and increased operational costs.

Each saw blade is intended to cut a specific material and work with a specific power saw.

BRASS

Only used to reinforce the folded strip along the back of backsaws and to make the screws that in earlier times held the blade to the handle.

IRON

Until steel replaced it, it was used for blades and the reinforcing strip on low-cost backsaws.

ZINC

Used only for saws made to cut blocks of salt, as formerly used in kitchens.

COPPER

Used as a Zinc alternative for salt-cutting saws.

STEEL

Used in almost every existing kind of saw. Due to its affordable price, flexibility, and its strength. It is suitable for most types of saws.

DIAMOND

Diamond saw blades can be used to cut hard, brittle, or abrasive materials such as stone, concrete, asphalt, bricks, ceramics, glass, semiconductor, and gemstone.

HIGH-SPEED STEEL (HSS)

HSS saw blades are mainly used to cut steel, copper, aluminum, and other metal materials

TUNGSTEN CARBIDE

Normally, there are two ways to use tungsten carbide to make saw blades:

1. Carbide-tipped saw blades

2. Solid-carbide saw blades

STTE was appointed as Harris Sawing’s official distribution agent in Saudi Arabia in 2020. Harris Sawing is a Kenyan company that its roots go back to 1919. It continuously updates its factory inventory, besides, installing the latest automated equipment for the manufacturing of circular saw blades, such as automatic TCT sharpening machines & automatic polishing machines.

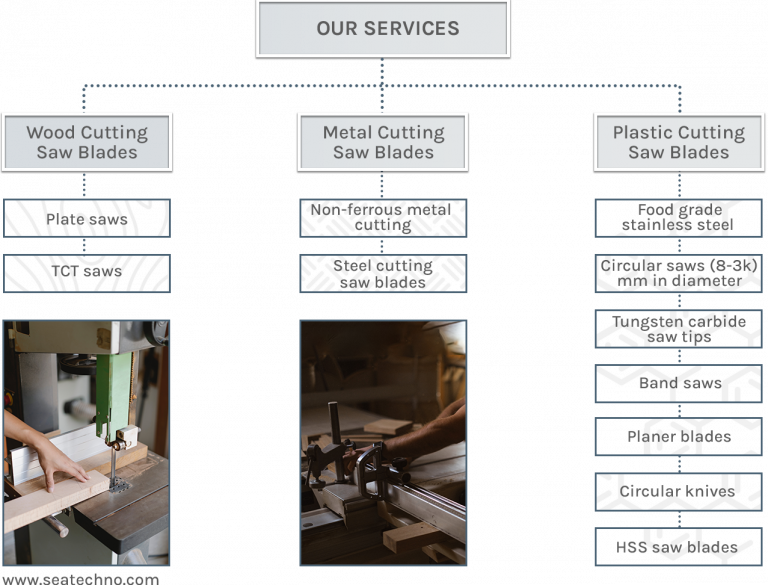

STTE’s imported industrial saw blades are manufactured to provide the smoothest cuts possible while also extending blade life. To meet your business or personal needs, we offer a comprehensive line of high-quality general-purpose and application-specific saw blades. Our saw blades are used in mills, cabinet shops, and woodworkers.

CHOOSING THE RIGHT SAWBLADE

Make certain that the blade you choose is appropriate for the material you need to cut and that it fits your saw. You would consider a number of requirements.

01

Define your needs

First and foremost, you must consider the type of saw you are using. Take into count that the blade intended specifically for one type of saw is not safe to use on another type of saw, even though the blades are the same size.

02

Number of Teeth

A saw blade consists of a series of teeth that perform the cutting action. More teeth result in a smoother cut, while fewer teeth mean that the blade removes more material. The angle and design of the tooth factor into blade speed, cut quality, and the type of material it can cut.

03

Hook angle

The hook angle refers to the angle at which the teeth will engage the material being cut. Using a saw blade with a positive hook angle to cut metal, such as aluminum trim, can be dangerous because the blade will have a strong tendency to grab the material causing the operator to lose control.

04

Blade flatness

Once the blade is mounted on the surface, it should be flat. So when it turned, it should not have any sizeable wobble or drift. Not to forget to mention that flatness helps to ensure that all teeth meet the workplace equally.